Any HVAC unit, be it Trane, Carrier, Lennox, etc. can have its performance compromised by poor installation. Installation problems plague the HVAC industry. Proper sizing of the equipment, duct design, correct airflow and refrigerant charge are all key elements in the installation process that can’t be shortcut, if you are going to achieve the benefits of the new equipment you are investing in. The quality of your new system “installation” will have more bearing on the performance of your new HVAC system than the equipment itself.

Another dimension of this problem is that this new equipment gets installed in a house and if the house has problems with the thermal and pressure envelope the comfort and efficiency gains are not going to be realized. Many homes have poor duct design, undersized returns, duct restrictions, duct leakage, air barrier issues, insulation defects and inadequate solar control. There HVAC salesman who ignore these issues still call themselves “comfort consultants,” which is an obvious misnomer.

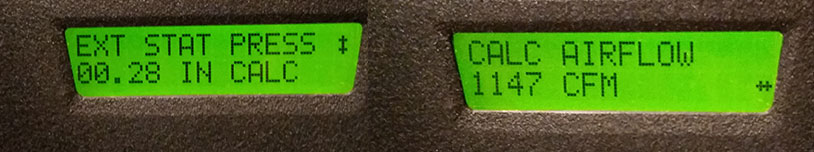

Although we primarily focus on equipment installation issues in this article, you will quickly see that it is impossible to ignore the whole house in this process if we are going to do a proper load calculation or deliver the correct amount of air to a room to satisfy the load calculation. When performing load calculations we must make determinations about the house’s R-values, infiltration, duct leakage…. At Advantage Home Performance we are expanding the definition of a quality installation.